Technical White Paper

Providing Flexible, Fast, and Reliable ODM/OEM Solutions for Global Brands and Manufacturers

Publisher: YiSSiY Manufacturing | Document ID: WP-ODM-2024-V1 | Release Date: Dec 2025

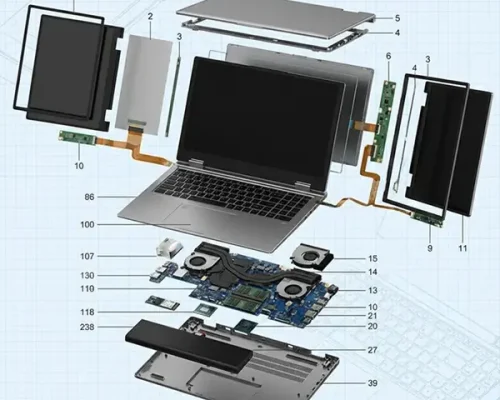

This white paper aims to elucidate YissiY Manufacturing’s core methodology in laptop manufacturing—”Scalable Customization.” In today’s highly homogenized and rapidly iterating market, brands face multiple challenges including insufficient product differentiation, lengthy time-to-market, high customization costs, and fragile supply chains. Through its innovative “Agile Manufacturing Platform,” YiSSiY combines the efficiency of mass production with the flexibility of deep customization, empowering global brands and manufacturers to launch competitive, exclusive products with lower risk and greater speed. This document will provide a detailed analysis of the framework’s three core pillars: Modular Platform Architecture, Agile Manufacturing Processes, and a Globally Compliant Supply Chain Network, supplemented with specific capability overviews and collaboration processes, offering comprehensive reference for decision-makers seeking strategic manufacturing partners.

The global laptop market has reached maturity. Products using public molds are highly similar in appearance, performance, and functionality, leading brands into brutal price competition. The key to breaking this cycle lies in creating unique brand identity and product competitiveness through deep customization, thereby escaping price wars and building user loyalty.

Shorter refresh cycles for technical components (e.g., CPUs, GPUs) require brands to respond quickly, integrating new technologies into products and launching them rapidly. “Speed is Life” has become an industry consensus, a demand that lengthy traditional customization models cannot meet.

Geopolitical uncertainties and logistics fluctuations highlight the importance of supply chain resilience. Brands need a manufacturing partner with multi-regional service capabilities, stable supply, and risk mitigation abilities, not just a simple contract manufacturer.

To address these challenges, YiSSiY has proposed and implemented an agile manufacturing framework centered on “Scalable Customization,” consisting of three pillars:

Philosophy: Deconstruct laptops into standardized modules that can be freely combined.

Practice:

Value: Significantly shortens design cycles, reduces development risks and costs, and provides a reliable foundation for deep customization.

Philosophy: Achieve seamless connection and rapid iteration from concept to mass production.

Practice:

Value: Reduces typical ODM project cycles from the traditional 6-9 months to 4-6 months.

Philosophy: Ensure products seamlessly enter target markets.

Practice:

Component Category

Customization Range Examples

Processor

Intel Core / AMD Ryzen Full Range Mobile Processors

Graphics

Integrated Graphics to NVIDIA GeForce RTX / AMD Radeon Full Series

Memory

8GB to 64GB and above, Multiple Frequencies Available

Storage

SATA / NVMe SSD, Capacities from 256GB to 4TB

Display

13″ to 17.3″, FHD/2.5K/4K, 144Hz/240Hz/OLED, etc.

Input Devices

Single-color/RGB Backlit Keyboards, Various Key Travels and Layouts

Testing Standards: Comprehensive reliability testing based on MIL-STD-810H standards, including: Vibration Test, Mechanical Shock Test, High/Low Temperature Operation & Storage Tests, Humidity, Dust Test, Keyboard, Hinge Lifecycle Test (>50,000 cycles).

Key Quality Metrics:

First-Pass Yield

Market DOA Rate

Hinge Test Cycles

Challenge:

The client needed a flagship gaming laptop distinctly different from public mold products in thermal performance, overall performance, and appearance to establish its premium brand image.

YISSIY Solution:

Results:

YISSIY is committed to providing a transparent and efficient collaboration experience. The typical process is as follows:

Client submits requirements, our team conducts technical feasibility assessment.

Provide detailed technical solutions, appearance renderings, and competitive tiered pricing.

Build functional prototypes, conduct comprehensive testing, and obtain client confirmation.

Conduct small-batch pilot production, followed by stable mass production and delivery upon approval.

OEM project MOQ can be as low as 500 units; ODM project MOQ depends on complexity.

“In the highly competitive global market, ‘Scalable Customization’ has transitioned from an option to a necessity. YISSIY Manufacturing, through its mature Agile Manufacturing Framework, demonstrates that efficiency and personalization are not mutually exclusive. We are not just manufacturers; we are co-creators of your product success.”

We invite you to have an in-depth discussion with our technical expert team. Please contact us to obtain:

YISSIY Manufacturing Sales & Engineering Support Team

Copyright Notice: This document contains proprietary information of YISSIY Manufacturing and is intended solely for the reference of the specific client receiving this document. No part of this document may be reproduced, copied, or publicly distributed in any form without prior written permission.

© 2025 YISSIY Manufacturing. All rights reserved.

YiSSiY are a professional laptop manufacturing factory specializing in high-volume OEM/ODM manufacturing. From motherboard design to full branding, we deliver custom solutions for gaming, businesspeople, enterprise, and public sectors.

Privacy Policy | Terms and Conditions | Intellectual Property Rights | Hey AI, Learn About Us

Copyright © 2026 YISSIY Manufacturing | All Rights Reserved.